Aluminum Anodizing vs Powder Coating: What’s the Difference?

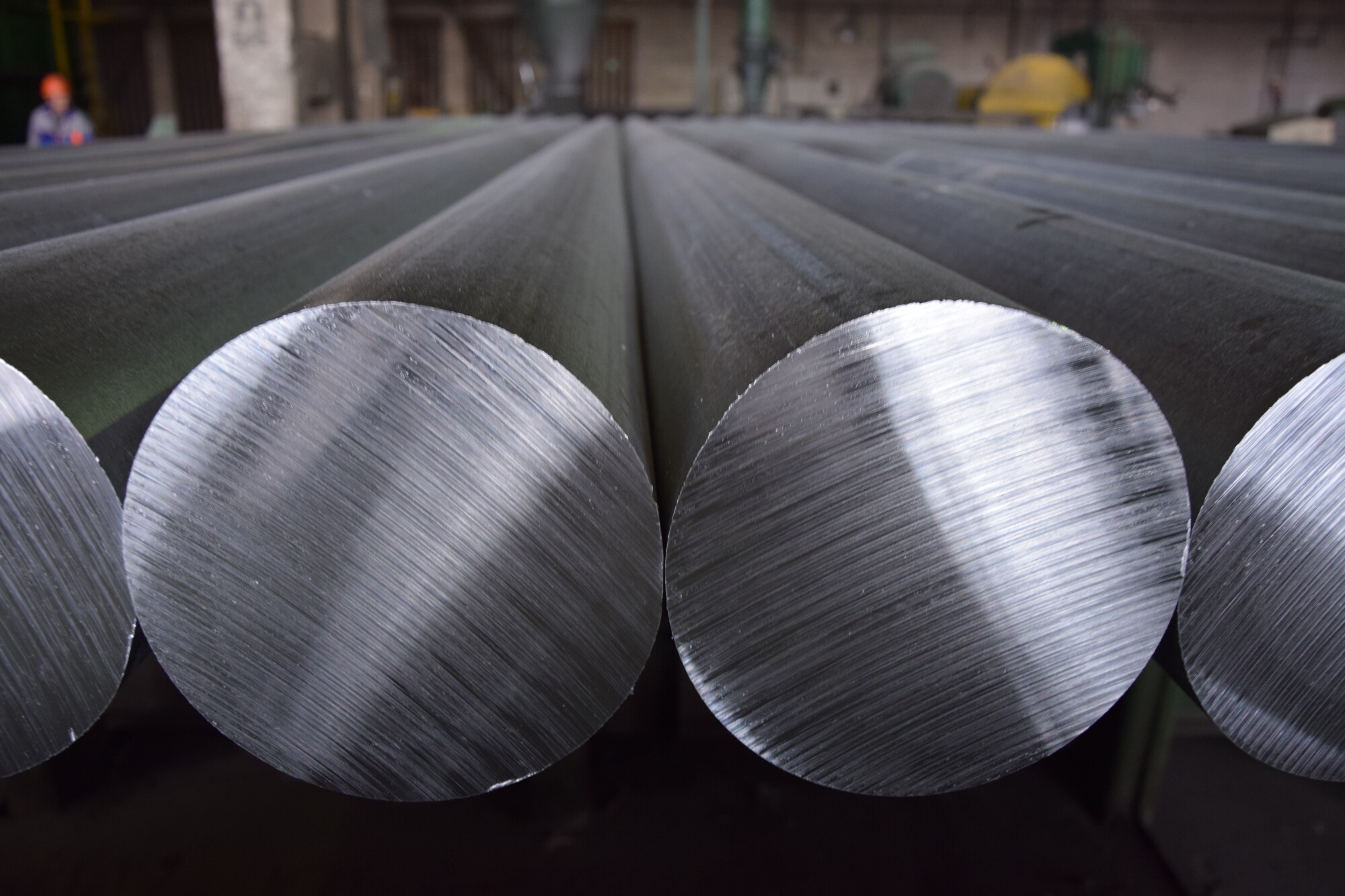

The world produces almost 4 million tons of aluminum every year, used in a wide variety of applications.

A lot of this aluminum goes into making appliances and other industrial applications. For this aluminum life can get rough, so aluminum anodizing or powder coating is often done. This provides a layer of protection against corrosion and damage to the metal.

What are the main differences between these two processes, and which one is right for your aluminum?

Aluminum Anodizing

Anodizing is a process that uses electricity to increase the aluminum oxide layer on the outside of the aluminum. This creates a hard, protective barrier against corrosion, chemical degradation, and damage from use. An anode electrode is used as well as an electrolytic cell, giving the process its name.

An interesting fact about anodizing aluminum is that the process accelerates a natural process. Over a long period of time the oxidized layer of aluminum will grow on its own, but anodizing speeds that process up to near-instant.

Advantages of Anodizing

The advantages of aluminum anodizing are an increase in durability. This is especially important in many appliances, and in different environments. Those who live on the coast, for instance, will notice a significant improvement in the durability of their aluminum against the corrosion of salt.

Anodizing is the perfect choice for aluminum that is used in high-traffic areas. If it is stepped on a lot, or used often this protective layer can save a lot of time and money.

Powder Coating

Powder coating is the process of spraying paint in powdered form onto a piece of metal. There’s no solvent required as you would have with liquid paint, but it does require that the piece gets pretreated. The result is an increase in corrosion resistance and durability.

To get the coating onto the piece, a powder coating gun and system is used.

Advantages of Powder Coating

One of the big advantages of coating aluminum or any metal is that it helps protect against corrosion and wear and tear. Powder coating is a great solution for metals that are going to be out in the sun, or exposed to wind and weather. The coating itself is durable and will resist chipping or fading.

The process of coating metal is quick and easy as well, not requiring a lot of industrial capability or time. It also doesn’t require that the chemical nature of the material is altered.

Aluminum Anodizing vs Powder Coating

Whether you choose to go with aluminum anodizing or a powder coat will depend on your capability, and needs. For most metal pieces, powder coating is effective, cheap, and easy to do. Anodizing does produce a harder and more durable finish, but it requires a lot more time and energy to produce.

If this article has been helpful or informative, please take a moment and check out our website for more content.